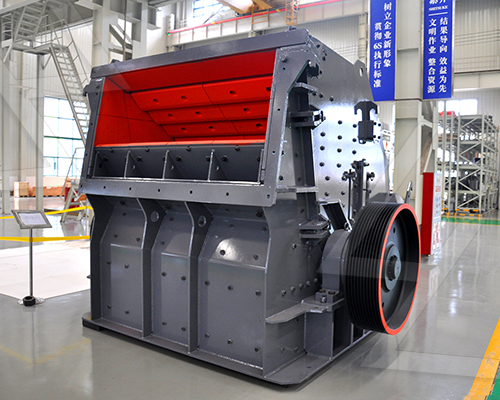

The Raymond mill (also known as a roller mill) is widely used for grinding non-flammable and non-explosive materials with Mohs hardness below 7 and humidity less than 6%. The grinder roller is one of the key easy-wear parts in the Raymond mill, along with the grinding ring, blade, and other components.

Grinder Roller – Key Wear Part in Raymond Mill

Grinder Roller – Key Wear Part in Raymond Mill

The grinder roller is subjected to constant friction and pressure during operation, making it prone to wear. Proper maintenance and timely replacement are crucial for optimal performance.

# Common Wear Parts in Raymond Mill:

1. Grinder Roller – Directly contacts the material; wears out over time.

2. Grinding Ring – Works with the roller to grind materials.

3. Blade (Shovel) – Feeds materials between the roller and ring.

4. Bearing & Seal Rings – Ensure smooth rotation but wear due to dust.

5. Classifier Blades – Control fineness but degrade with abrasive particles.

# Factors Affecting Wear:

– Material hardness & abrasiveness

– Grinding pressure & speed

– Maintenance frequency

– Lubrication quality

# Solutions to Reduce Wear:

✔ Use high-quality alloy rollers (e.g., high chromium, manganese steel).

✔ Regularly inspect & replace worn rollers/rings.

✔ Adjust grinding pressure to reduce excessive.jpg) iction.

iction.

✔ Ensure proper lubrication of bearings & moving parts.

When to Replace Grinder Rollers?

– Reduced grinding efficiency

– Increased power consumption

– Unusual noise/vibration

– Visible cracks or severe wear on rollers

Where to Get Replacement Parts?

Most Raymond mill manufacturers or specialized suppliers offer OEM or compatible wear parts. Ensure dimensions match your model (e.g., 3R/4R/5R/6R series).

Would you like recommendations for specific material grades or suppliers? Let me know your Raymond mill model for precise part details!